Non-contact measurement has revolutionised the manufacturing industry. The ability to measure intricate and complex features of a component with no contact has enabled unmanned, automatic and digitalised inspections that traditional CMM systems are unable to produce. This elevates the accuracy of manufacturers component measurements, whilst maximising capacity across the shopfloor. Non-contact measurement enables manufacturers to collect precise and meaningful measurement data without the risks of contact measurement.

The Carfulan Group’s multi-sensor measurement specialist company, OGP UK, offers non-contact measurement sensors that transform inspection processes across the engineering and manufacturing market in key industries including aerospace, automotive, medical and pharmaceutical, providing more accurate and comprehensive measurement data and reporting.

What is non-contact measurement?

Non-contact measurement sensors are modern metrology technologies that obtain measurement data from a component without physical contact, eliminating the risk of influencing the shape, surface or component itself. The sensors can be used to measure a wide variety of objects with intricate features and complex geometries with superior reliability and repeatability to reach angles and dimensions previously impossible with contact measurement methods (CMMs, Vernier callipers and micrometres). Non-contact measurement technologies automatically measure features including angle, radius, edge break or surface finish to ensure components comply to the original design specifications.

Non-contact measurement systems quickly collect large amounts of data, making them ideal for inspecting complex shapes with multiple features. This data can be exported in a number of different formats and is then directly transferred into a database to ensure the data remains clear, traceable and stored. The digitalisation of these inspection technologies allows the data to be recorded for statistical process control and traceability purposes, enabling the operator to react to any non-conformities in real-time. This results in faster and high-quality production processes, without the need to make contact with the object in any way.

Non-contact measurement is commonly utilised in industry’s including pharmaceutical, medical, automotive and aerospace to increase throughput and reduce bottlenecks, improve efficiency and reduces costs. As non-contact measurement continues to advance, becoming more affordable and accessible, it is fast becoming an essential for modern day manufacturing and production industries.

OGP UK non-contact measurement systems

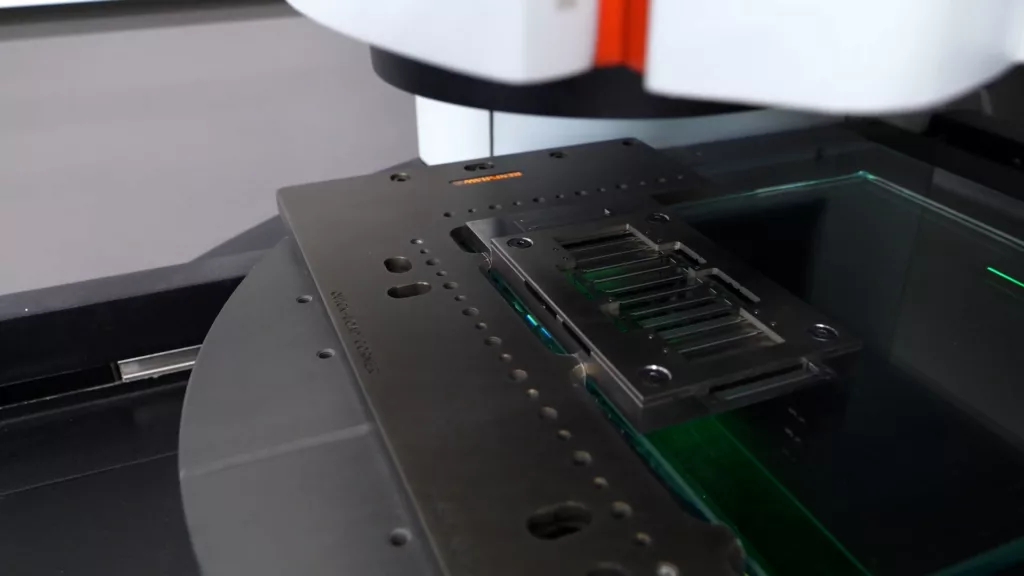

OGP UK provides the best-in-class multi-sensor measurement systems, combining contact and non-contact inspection sensors for unrivalled performance in the quality control of manufactured parts and components. Non-contact measurement systems have developed a multitude of sensors to achieve advanced measurement and inspection capabilities, as well as more accurate and repeatable data results.

OGP UK offers two state-of-the-art non-contact measurement technologies: Optics and Lasers.

- Lasers measure the distance between the laser and the object being measured using a beam to create a 3D model of the object. Lasers are perfect for dimensional inspection as they are fast and efficient, providing a wide variety of retrofits, enhanced versatility and intricate assessments of hard-to-reach features.

- Optics determine the dimensional profile of a part by taking a series of pictures of its surface. Optical sensors are high-speed, high-resolution, and accurate with telecentric optics, high-resolution cameras, through-the-lens laser scanning, smart probes, and zoom/fixed optics.