Manufacturers in today’s competitive landscape are constantly seeking ways to improve their efficiency, quality, and overall profitability. In an era where data is the new currency, Prolink UK’s software solutions offer powerful data insights that empower manufacturers to have greater visibility across the shopfloor.

Prolink UK software solutions offer a comprehensive suite of tools that can help manufacturers achieve these goals by providing real-time data collection and analysis, eliminating human error, and ensuring unrestricted access to data from anywhere and at anytime.

5 reasons why manufacturers should integrate Prolink software solutions across their shopfloor

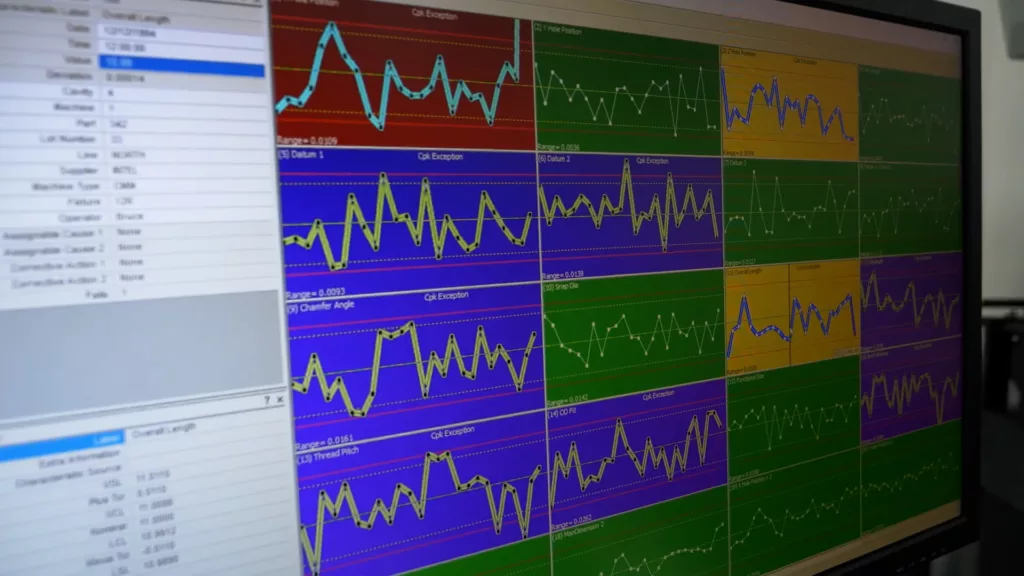

1. Gain full control & management of shopfloor data

Prolink’s software solutions offer real-time data collection and analysis capabilities to enable manufacturers to gain full control over their shopfloor data. It can identify potential issues, trends, and patterns, providing full visibility before any production disruptions or costly defects. Prolink software solutions offer consistent reporting and quality management across multiple machines, shopfloors and locations, regardless of their size or complexity.

2. Unparalleled accessibility to data

Organisations are able to gain valuable insights into their data anywhere, anytime, and on any device, using Prolink’s software solutions. This revolutionary accessibility empowers shopfloor engineers to access critical data directly from their workstations, whilst senior management can monitor production progress and quality control measures, making critical adjustments and improvements as needed.

3. Eliminate human errors across all data

Prolink provides manufacturers with a powerful tool to eliminate human error and streamline shopfloor operations. Eliminating manual data entry helps manufacturers to achieve operational excellence and accuracy by eliminating the risk of human input errors. By automating data collection and analysis, Prolink software solutions significantly improves efficiency, reduces costs, and enhances productivity.

4. Bespoke data access at every level

Prolink’s customised data access and reporting empowers organisations with real-time visibility and data-driven insights at every level. Senior management can tailor information to specific roles and departments to ensure that all employees have access to the data they need to optimise production processes. They can use this data to identify potential issues early on and take corrective actions.

5. Scalable to every shopfloor

The scalability of Prolink software solutions offers an ideal choice for manufacturers of all sizes. This software can seamlessly integrate with any shopfloor, effectively collecting data from over 350 CMM’s and metrology gauges. It can adapt to the evolving needs of any manufacturing environment, from small workshops to large enterprises with multiple shopfloors across multiple sites to inform decisions, optimise processes, and achieve operational goals.