Modern manufacturing is constantly advancing and developing, meaning accurate and precise part measurement is more critical than ever before.

For turned parts, achieving consistent, high-quality dimensions is crucial and requires measurement systems that can adapt to diverse geometries and deliver accurate results with unwavering reliability.

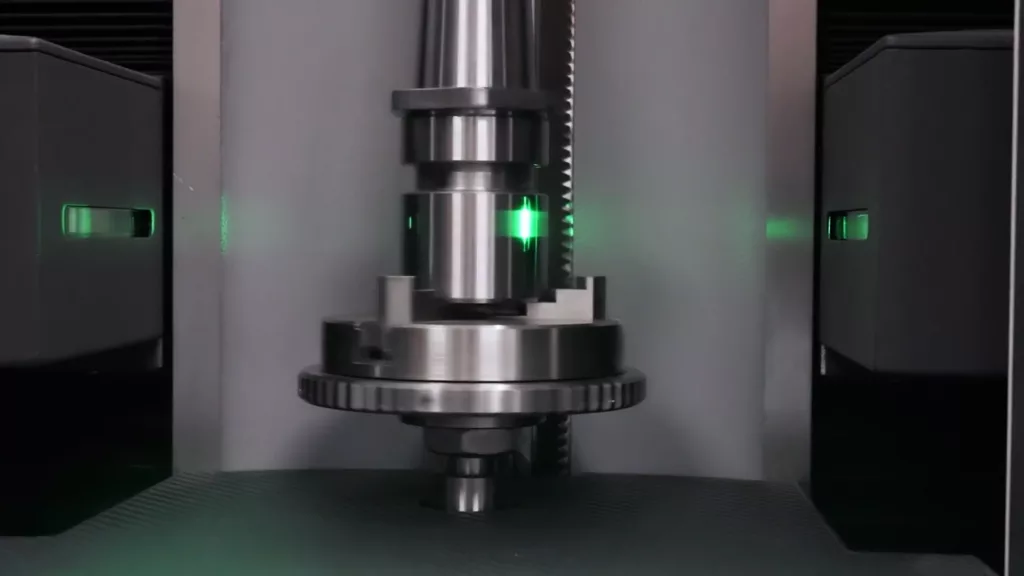

VICIVISION provides the most comprehensive range of turned part measurement machines to accommodate the diverse range of turned part inspection requirements. The comprehensive range of systems, powered by state-of-the-art technology, allows manufacturers to achieve unparalleled precision, optimised production, and high-quality products.

A measurement machine for any turned part requirements

VICIVISION UK provides the most comprehensive range of turned part measurement systems in the UK. Delivering state-of-the-art technology, VICIVISION UK caters for a variety of turned part shapes, sizes, and complexities. Their diverse range of optical measurement systems adapts to the vast array of diameters, lengths, and features within modern manufacturing.

PRIMA

Built for speed and efficiency, the PRIMA range tackles large parts with high throughput, ideal for high-volume production lines. The advanced telecentric lenses eliminate any distortion, ensuring consistent accuracy even on larger components including shafts and axles.

TECHNO

The TECHNO series offers microscopic technology for turned parts with intricate details and hidden features, magnifying complex geometries, revealing thread profiles and surface roughness with unmatched precision. It is the ideal choice for inspecting critical parts like medical implants and aerospace components, where even the smallest inaccuracies can have significant consequences.

X-Series

Combining high-resolution optical scanning with telecentric lenses, the X-Series delivers fast and accurate measurements of micro components. This makes it ideal for applications including micro-mechanical parts, dental implants and watch components.