As the manufacturing industry’s demands continue to grow, the technology and processes used by manufacturing companies must keep pace with modern advancements to remain competitive.

However, traditional manual tool setting methods are now outdated and struggle to provide the accuracy and repeatability required by modern manufacturers. Setting tools directly onto a machine poses a number of challenges, including time, cost and capacity.

What are the 5 key challenges with setting tools directly onto a CNC machine?

1. Limited machine capacity

Setting tools directly onto a CNC machine restricts their machining capacity, resulting in a large amount of downtime spent on set ups, changeovers and adjustments.

2. High costs

Whilst setting tools directly onto a CNC machines, the machine is inactive, not producing profitable products and parts.

3. Unreliable & inaccurate

Setting tools directly onto a CNC machine requires manual measurement and interpretation, increasing the risk of human error and leaving tool measurements susceptible to inconsistent readings from different operators.

4. High levels of scrap

Direct tool setting on machines relies heavily on operator interpretation and skill. This can lead to inaccurate tool positioning, resulting in inaccurate parts and increased scrap rates.

5. Limited measurement capabilities

Manual machine tool setting is limited in the complexity of their measurement capabilities. Some tool features are inaccessible which restricts the accuracy and understanding of whether or not the tool is in tolerance.

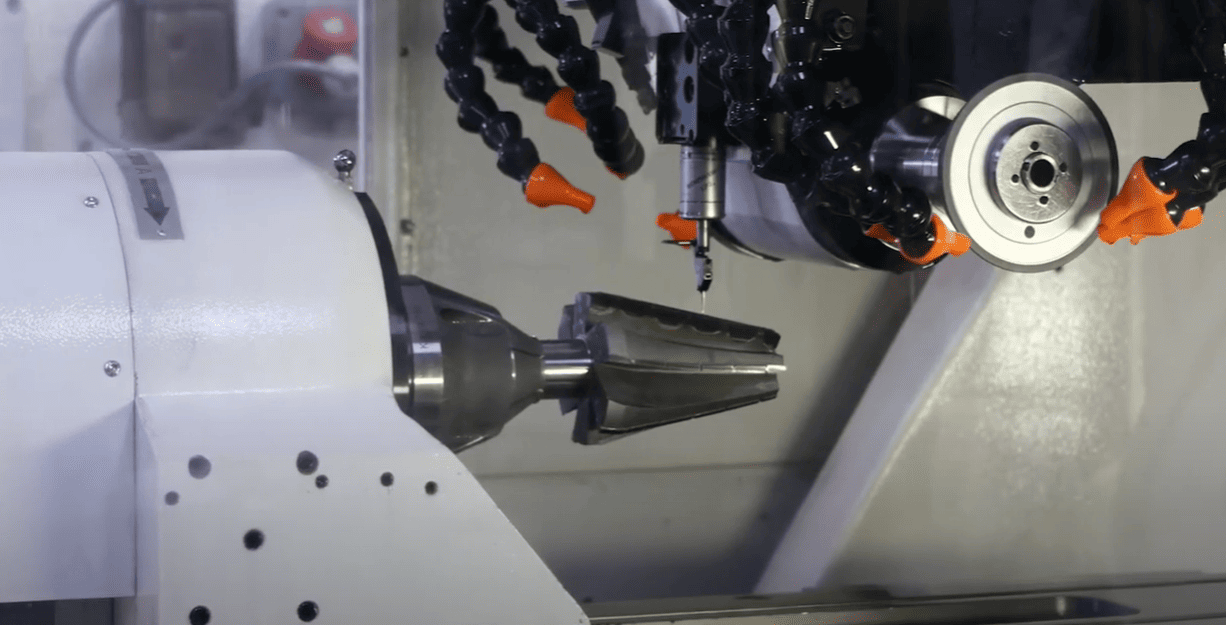

How does ZOLLER UK solve this problem?

ZOLLER’s state-of-the-art tool presetting and measuring solutions provide precise tool geometry data, enabling your machines to be at optimal performance. ZOLLER UK’s automated, non-contact tool presetters determine tool data away from the manufacturing machine, resulting in reduced setup times, increased productivity and the elimination of potential errors.