The 8 wastes is a core principle in manufacturing. Each waste represents an area where resources (time, money, and materials) are utilised without adding value to the final product. By identifying and eliminating these wastes, manufacturers streamline operations, reduce costs, and boost profitability.

Over the last century, the manufacturing industry has undergone a revolutionary shift.

The introduction of new technology and processes have increased the value of production whilst reducing the amount of work required to perform tasks.

At the heart of this transformation is the removal of waste. Waste can come in many formats including time, material, labour, as well as the utilisation of skill-sets and poor planning.

To remain competitive, manufacturing companies must eliminate waste from their processes. This not only streamlines operations but also reduces overhead costs whilst maximising productivity and profitability.

Originally developed in the mid-20th century, the eight wastes of manufacturing focus on streamlining production processes and maximising workforce potential. By eliminating these wastes, manufacturers ensure that every step in their process adds genuine value to the final product.

What is manufacturing waste?

Before discussing each specific type of waste, it is important to define what waste is.

Manufacturing waste is any expense or effort that does not produce a product the customer is willing to pay for.

What are the 8 wastes of manufacturing?

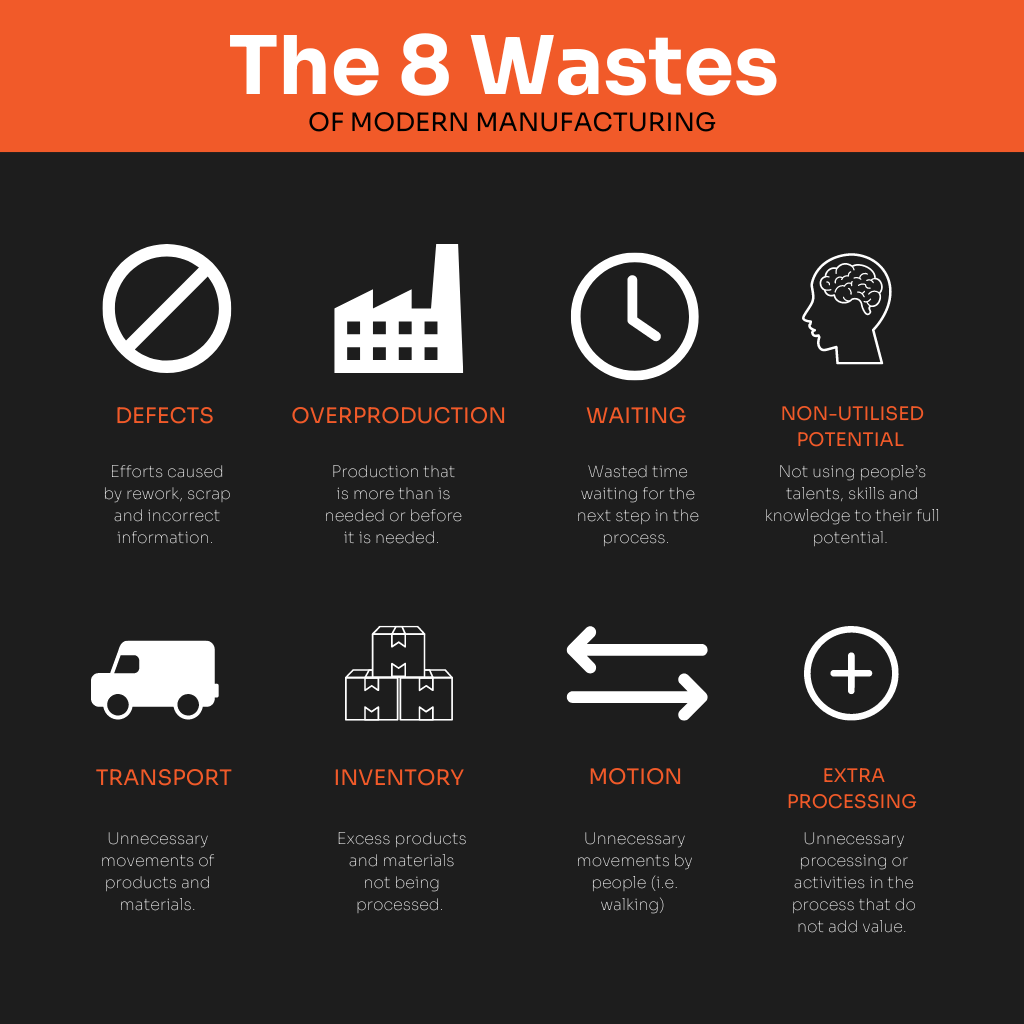

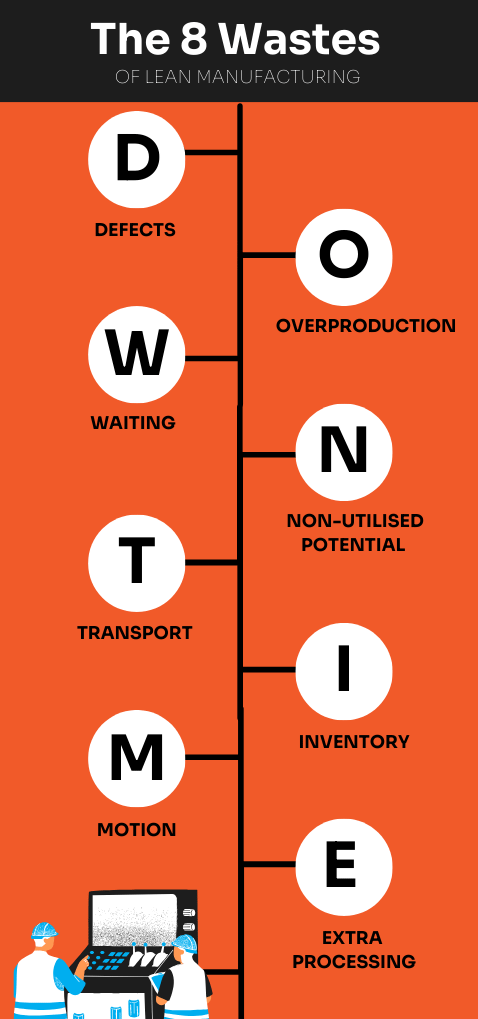

The eight wastes, commonly referred to as ‘DOWNTIME’ consist of Defects, Overproduction, Waiting, Non-utilised potential, Transport, Inventory, Motion and Extra processing.

The core seven wastes of manufacturing, known as ‘Muda’ in Japanese, were established by Taiichi Ohno, a key figure in the development of Toyota’s Production System (TPS) in the mid-20th century. The eighth waste, focusing on underutilised employee skills, was later added in the 1990s as the TPS gained wider adoption in the Western world.

Explore each of the eight wastes below.

The 8 wastes of manufacturing

Defects

Defects are a major source of waste in manufacturing, creating high levels of wasted time, money, resources and customer satisfaction. They incur large additional costs to operations through reworks, scrap, and inaccurate information, all of which generates no customer value or company profit.

Overproduction

Traditionally, manufacturers filled any downtime by producing additional parts and products. However, this leads to overproduction and creates a wasted burden of storage costs, extended lead times, and increased capital investment, whilst increasing the risk of these products becoming obsolete and unprofitable.

Waiting

High volumes of time are wasted in manufacturing processes due to excessive wait times. These delays can stem from a variety of sources including email lag, approval backlogs, slow software, material shortages, and idle equipment, wasting valuable production time.

Non-utilised potential

The most recent addition to the eight wastes is underutilised talent. When companies fail to recognize and utilise their workforce’s skills and knowledge, it hinders progress and process improvement. Disengaged employees, inadequate training, or improper tools prevent active problem solving on the shopfloor.

Transport

Waste in transportation arises from the unnecessary movement of materials, people, or equipment. This excessive movement can damage products, lead to defects, create rework, increase wear and tear on machinery, and accelerate employee fatigue.

Inventory

Waste in inventory stems from over-purchasing or overproducing goods without the customer demand. Having excess inventory, materials and stock on the shelves can lead to issues including product defects or damaged materials, greater lead times and an inefficient allocation of capital and consequently, more work is required to correct these defects.

Motion

Wasted motion specifically refers to any unnecessary movement by workers that doesn’t add value to the final product. This can include excessive walking, reaching for poorly placed materials, searching for misplaced files, sorting through disorganised inventory, or repeatedly adjusting components unnecessarily. These actions consume valuable production time without producing anything profitable.

Extra processing

Extra processing is when unnecessary steps are added to a product or service. This can include filling out paperwork and reports, over-engineered components, excessive analysis, or including features customers don’t need, all of which wastes resources and adds no value to the final product.