In modern manufacturing, achieving consistent, high-quality products requires comprehensive quality control over every element of the production process, beginning with tooling.

Maximising tooling performance requires unwavering precision and repeatability, ensuring every tool is accurate, and within the specified tolerances.

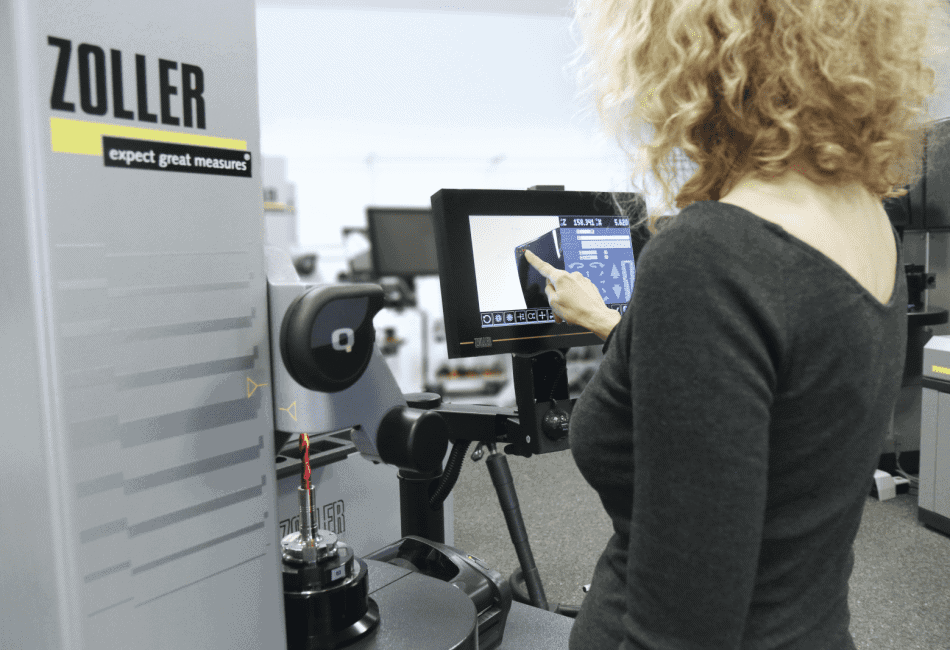

ZOLLER UK delivers world-leading precision tool presetting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing process. Their comprehensive suite of solutions allows manufacturers to maximise tooling performance across any shopfloor process.

Maximise tooling performance with ZOLLER

Unparalleled accuracy with non-contact measurement

Traditional contact-based tool inspection methods risk tool damage, impacting the performance and longevity of the tooling. ZOLLER eliminates this concern utilising high-precision optical sensors to capture detailed measurement data without compromising tool integrity, guaranteeing high quality cutting edges and reliable, accurate tool performance.

Standardised tool assembly

ZOLLER tool measurement and inspection systems analyse complex, critical dimensions and features including run-out and stick-out length. This ensures not only that the individual tool meets precise specifications but also that the entire assembly operates perfectly, eliminating any inconsistencies and production bottlenecks.

Extended tool life

ZOLLER’s advanced inspection technology performs comprehensive measurements, identifying even the slightest inaccuracies to ensure optimal tool usage. This prevents any damage from incorrect settings and tool wear, significantly extending tool life and maximising tooling performance.