ZOLLER UK enables you to unlock your manufacturing potential with tool presetting, inspection, storage and management solutions. Optimise your tooling with world-leading technology and innovative software to improve the efficiency of your manufacturing processes.

As the UK and Ireland’s sole partner for ZOLLER products, ZOLLER UK serves the whole of the UK and Ireland direct from the Advanced Innovation Centre in Derby. We offer a wide range of solutions for all tool presetting, inspection and management requirements, as well as service and maintenance, training, installation and application support.

Working With

All Industries

ZOLLER UK has a long history of working with a range of companies throughout the UK and Ireland who trust our knowledge and expertise to help them transform their tooling processes. We work with companies from all industries, so whether you are a small independent or a large multi-national, we promise to work with you to help you achieve optimal performance and end-product excellence.

ZOLLER’s comprehensive suite of tool presetting, inspection, storage and management solutions seamlessly integrates into existing shopfloor processes, elevating them to a new level of performance. They have transformed the way tools are managed, offering significant time and cost saving solutions.

Expert Knowledge

Whether you are looking to reduce tool set-up times or improve the quality of parts you are producing, ZOLLER UK can provide expertise and experience to find the right solution for you. We have unrivalled knowledge in how to maximise the productivity and reliability of your tooling, helping you to save the most time and amplify your production.

ZOLLER’s state-of-the-art tool management solutions empowers manufacturers to elevate their operations to new heights by providing cutting-edge technology that enhances efficiency, optimises processes, minimises scrap, and guarantees tool accuracy.

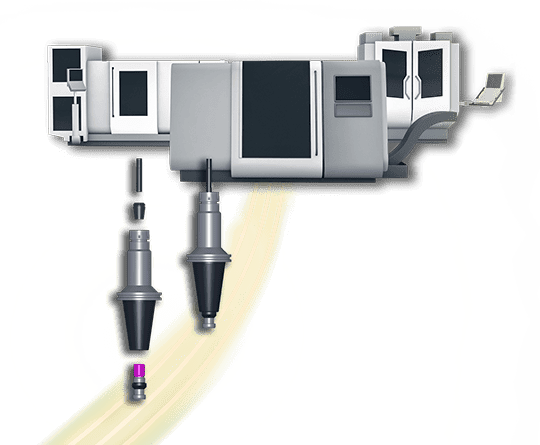

ZOLLER solutions significantly speed up production times by reducing machine downtime and increasing CNC machine utilisation. ZOLLER tool presetters can preset tools in seconds, transferring the data directly to the CNC machine using RFID chips, ZidCode, or barcodes. This can offer significant time savings per shift, leading to hundreds of hours saved and converted into production time.

ZOLLER UK delivers world-leading precision tool setting, inspection, storage and management solutions, adding improved efficiency and value to any manufacturing and production processes. ZOLLER’s tool management solutions optimise productivity across the shopfloor, maximising machine capacity whilst ensuring accuracy and consistency of every product.

Optimised shopfloor production efficiency is vital for modern manufacturers in an increasingly competitive market. Manufacturers need to ensure fast production, short turn-arounds and competitive pricing without sacrificing on product quality. When a manufacturing shopfloor is working at full capacity, the immediate thought is to buy another manufacturing machine to increase capacity… but what if there was a way to increase capacity without buying another machine and instead optimising the existing machines production capacity for a fraction of the price?

ZOLLER’s comprehensive suite of tool presetting, inspection, storage and management solutions seamlessly integrates into existing shopfloor processes, elevating them to a new level of performance. They have transformed the way tools are managed, offering significant time and cost saving solutions.

It’s robust and modular design, make the venturion the ideal tool presetting solution for every CNC production environment. Its enhanced structural integrity is complemented by maximum flexibility and precision, ensuring quality standards in manufacturing.

powerShrink takes less than 10 seconds to shrink-clamp a tool, while unclamping and cooling is done within 40 seconds, depending on the tool diameter. You’ll be ready for production in under a minute. Manufacturers who use powerShrink benefit from a high degree of rotation accuracy, long tool life, and reduced tooling costs, setting quality standards in manufacturing.

ZOLLER’s tool management solutions ensure the right tool is in the right place at the right time, all from one central database. This contributes to faster setups, reduced downtime, and increased productivity, enhancing your tool inspection and measurement solutions.

DoorCo

Macclesfield, United Kingdom

Learn how composite door manufacturer DoorCo implemented ZOLLER tool presetting technology to improve set-up times, reduce manufacturing scrap and increase their production capacity.

Unlock your manufacturing potential with ZOLLER UK’s range of tool presetting, inspection, storage and management solutions.

With measuring technology 4.0 solutions from ZOLLER, you are optimally positioned for the networked future, the Smart Factory.

In smart manufacturing, data plays an essential role. Image the entire production process in advance, safeguard the real production process.

Learn more about our tool presetting, inspection, storage and management solutions. Discuss your applications or request more information by filling out the form to the right. One of our expert engineers will be in touch to discuss everything ZOLLER.

Or call us on 01283 499566

Office Address

Faraday House,

Woodyard Lane,

Foston,

Derby

DE65 5BU

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House, Woodyard Lane,

Foston, Derby, DE65 5BU