As engineering and manufacturing industries continue to advance, guaranteeing high-quality, right-first-time components is vital to remain competitive within the market. Sliding head lathes are often used to produce small, precision parts in high volumes, and any inaccuracies, waste or scrap can have a significant impact on production and profitability.

The Carfulan Groups specialised turned-part measurement company, VICIVISION UK,provides high performance, non-contact measurement systems for turned parts that can operate directly on the shopfloor next to sliding head machines. By partnering with VICIVISION UK, companies can be confident that they are getting the best possible solutions for inspecting and improving the quality of their turned parts.

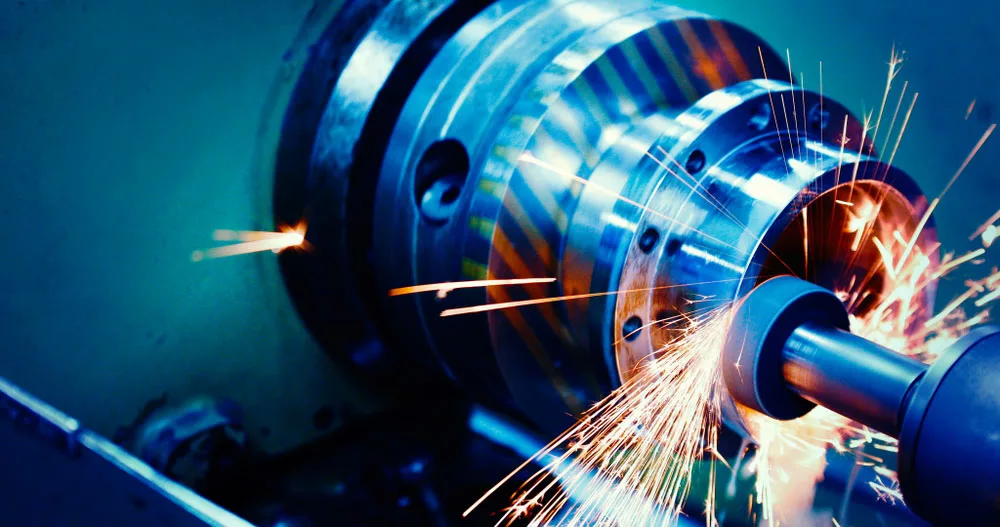

Citizen L20 sliding head lathe

Star SR-32J11 type A sliding head lathe

Why VICIVISION UK is the perfect partner for sliding head lathes

Scrap & waste reduction

VICIVISION’s measurement systems help operators minimise waste by analysing measurement data to identify areas for improvement, such as cutting speed or feed rate. This ensures accurate and consistent measurements, leading to higher quality parts and reduced scrap.

Improved accuracy

Improved accuracy is achieved when using VICIVISION’s measurement systems due to their high accuracy and precision, with sub-micron repeatability. This means that they can detect even the smallest defects on turned parts, ensuring that parts are produced to the desired specifications.

Increased speed

Rapidly measure complex turned parts on the shopfloor with VICIVISION to provide real-time feedback on the machining process. This feedback can be used to adjust the lathe’s parameters, helping operators produce high-quality parts, in high volumes, in quicker times.

Shopfloor ready

VICIVISION’s measurement systems are designed specifically for use on a shopfloor environment and to sit alongside sliding head lathes. Due to their small machine footprint, they can be quickly and easily integrated into existing production lines, and positioned next to sliding head lathes for immediate measurement of components.

Comprehensive reporting

Comprehensive reports, including SPC charts, histograms, and trend charts, provide detailed insights into the quality of turned parts being measured. These reports can be customised to the specific needs of the customer, highlighting key metrics such as the percentage of parts within tolerance for each critical dimension or the average and standard deviation for each dimension.

Ease of use

VICIVISION’s measurement systems are entirely user friendly, making them easy to use and quick to set up. This makes them ideal for the fast-paced environment of a sliding head lathe, where operators need to be able to measure parts quickly and accurately to keep production on schedule. Intuitive software and automated features guide the operator through the measurement process.