3D printing, or additive manufacturing, is the process of making three dimensional objects from a digital file. The development of these technologies has revolutionised multiple industries including aerospace, automotive and medical.

Initially, 3D printing was used almost solely for prototyping, but in recent years 3D printing has surpassed expectations as the discovery of new applications has evolved, developing new purposes and capabilities within a vast range of sectors. 3D printing is a powerful and expanding technology that can create completely customisable parts and prototypes faster than traditional methods, and with more flexibility than ever before.

What is 3D printing?

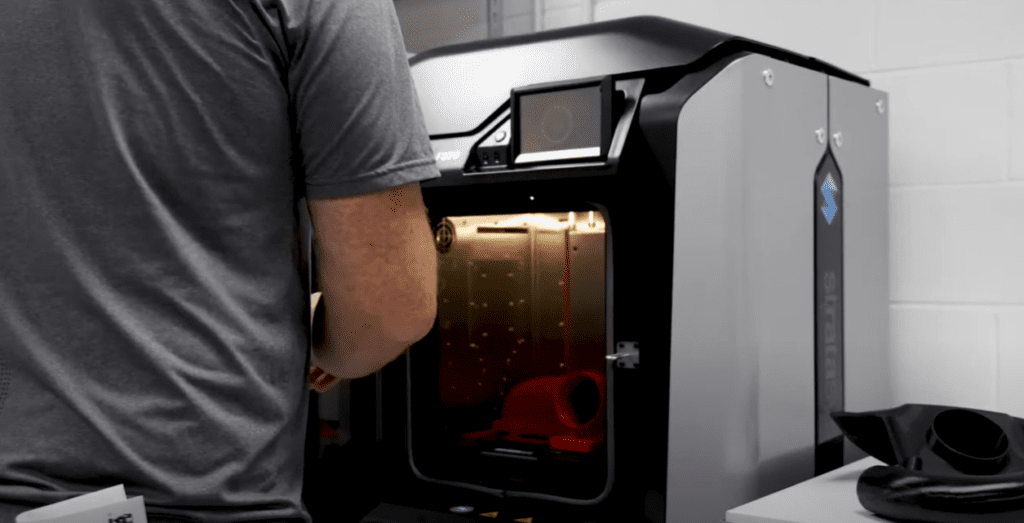

3D printing offers fast, versatile, accurate and repeatable products and prototypes that are fully customisable to each and every consumer. 3D printing enables the production of complex shapes by building up layers of the desired object until it is complete. This ‘additive’ process doesn’t require a block of material or a mould, unlike traditional manufacturing methods, because the object is built from scratch, stacking and fusing together layers of material.

As 3D printing technology has continued to evolve, it has developed a vast range of materials, including thermoplastics, metals, resins and ceramics to turn digital files, created using CAD software, into physical objects. With almost no set-up time or costs, 3D printing is ideal for prototyping and low volume production.

How does 3D printing work?

3D printers have a variety of technologies that use a multitude of techniques . Depending on the technique, 3D printers can use a variety of materials, rapidly producing key prototypes, jigs, fixtures and even end-use products in almost any geometry.

The standard process can be separated into 3 steps:

- A virtual design of the object is created using computer-aided design (CAD) software. This is a blueprint for the 3D printer to read and use when building the 3D printed object.

- Once the virtual model is made, it is sliced into thin horizontal cross-sections to represent each layer of the product.

- Using the data and information from the cross sections, the 3D printer then prints the product layer by layer, fusing together and solidifying the polymer materials to form the final product.

Key technology in industries including:

Aerospace

Automotive

Medical

Consumer Goods

Benefits of 3D printing:

- Rapid prototyping

- Design freedom

- Total customisation capabilities

- Reduced waste

- Greater control of design variables

- Wide range of materials and colours

- Produces high-performance and accuracy parts

- Reduces development timeframe

- Reduces costs

- Produce objects with complex geometries

- On-demand production

- Affordable start up costs