Multi-sensor metrology uses multiple sensors to measure different aspects of a workpiece. It is becoming increasingly important in the manufacturing industry because it offers a number of advantages over traditional single-sensor metrology systems, including speed, versatility and accuracy.

What is multi-sensor metrology?

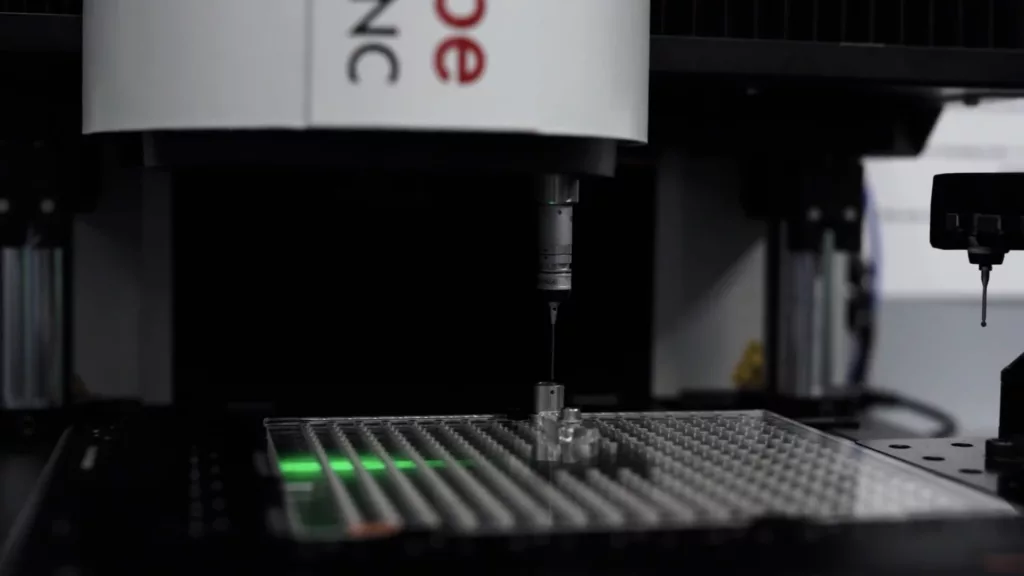

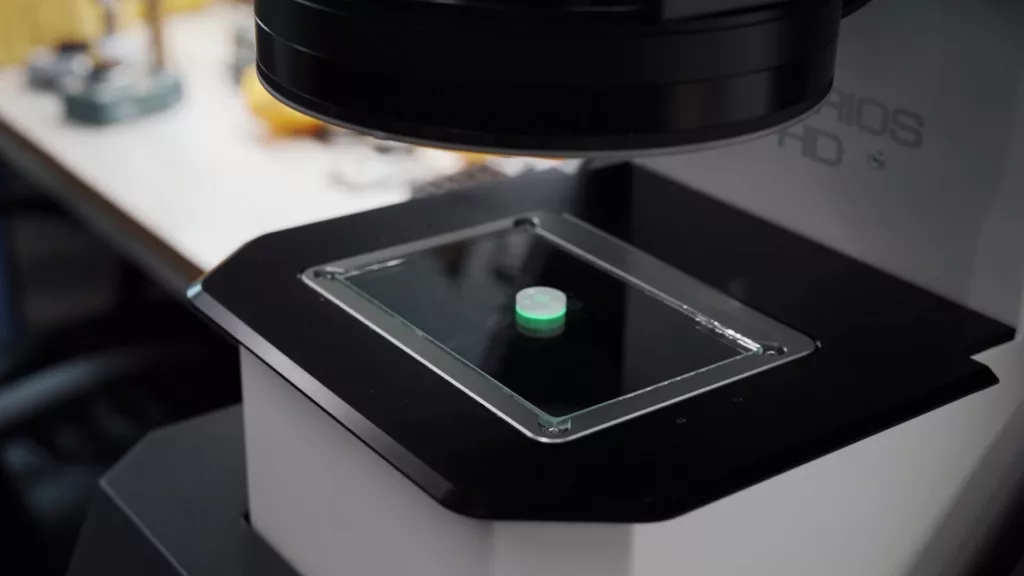

Multi-sensor metrology is a measurement technology, integrating multiple sensors and measurement devices to collect data and measure the dimensions and other properties of a component. Multi-sensor metrology systems offer improved measurement speed, accuracy, efficiency, and versatility in a variety of applications.

The range of contact and non-contact sensors produce comprehensive, detailed and accurate measurement reports that transform quality control and inspection processes.

OGP UK provides best-in-class multi-sensor measurement systems combining optics, lasers, rotaries and probes for unrivalled performance in the quality control of manufactured parts and components.

What are the benefits of multi-sensor metrology?

- Speed of Measurement: Using multiple sensors simultaneously or sequentially can reduce the time required for a measurement inspection, collecting data faster and helps accelerate decision-making processes.

- Comprehensive Measurement Reports: Multi-sensor metrology systems capture a wide range of component features and properties, including dimensions, surface textures, colours, shapes, and internal structures. The comprehensive inspection leads to increased accuracy, detail and analysis of the component measurements.

- Improved Accuracy and Precision: By integrating a variety of sensors within a single inspection, multi-sensor metrology improves measurement accuracy. It optimises each sensors specialist capabilities to achieve the most precise and informative measurement data.

- Versatility and Adaptability: Multi-sensor measurement systems can be tailored to the specific application and components being measured. Depending on the characteristics of the object and the parameters of interest, you can select and combine sensors to optimise the measurement process for different tasks.

- Reduced Setup and Calibrations: Instead of calibrating and setting up multiple individual sensors, a single integrated system can simplify the calibration process, reducing the time and effort needed for setup, enhancing overall efficiency.

- Cost-Effective Investment: Multi-sensor metrology systems are a cost-effective investment as it improves efficiency, reduces errors rates, and the need for multiple measurement systems.

- Enhanced Combined Data and Integration: Multi-sensor metrology integrates data from various sensors, revealing correlations and insights that may not be apparent from isolated measurements.

- Improved Quality Control and Assurance: Improved quality control and assurances are achieved when using multi-sensor metrology measurements as they help in identifying defects, inconsistencies and deviations from the original design specifications, ensuring that products meet quality standards.

- Enhanced Problem Solving and Decision Making: The comprehensive measurements provided by the multitude of sensors being used, produces a clearer understanding of the component when analysed, helping to facilitate more informed and data driven decision-making.