Turned Part Measurement Systems

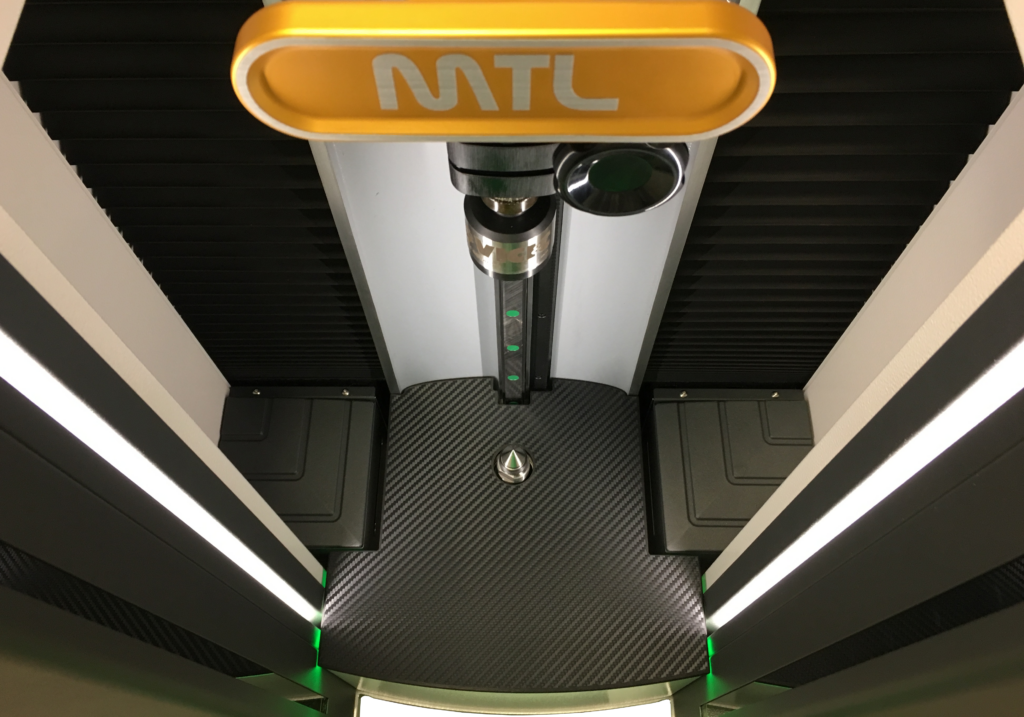

VICIVISION UK provide specialist high performance, non-contact measurement systems for turned parts and cylindrical components. Solve complex geometries in one cycle with VICIVISION and capture thousands of unique data points every second.

Inspection Simplified

As the UK’s sole partner for VICIVISION products, VICIVISION UK serves the whole of the UK and Ireland direct from the Advanced Innovation Centre in Derby. We offer a wide range of solutions for all part inspection requirements, as well as service and maintenance, training, installation and subcontract measurement.

Working With

Leading Industries

VICIVISION UK has a long history of working with a range of companies throughout the UK who trust our knowledge and expertise to help them transform their inspection capabilities. We work with companies from all industries, so whether you are a small independent or a large multi-national, we promise to work with you to help you achieve optimal performance and end-product excellence.

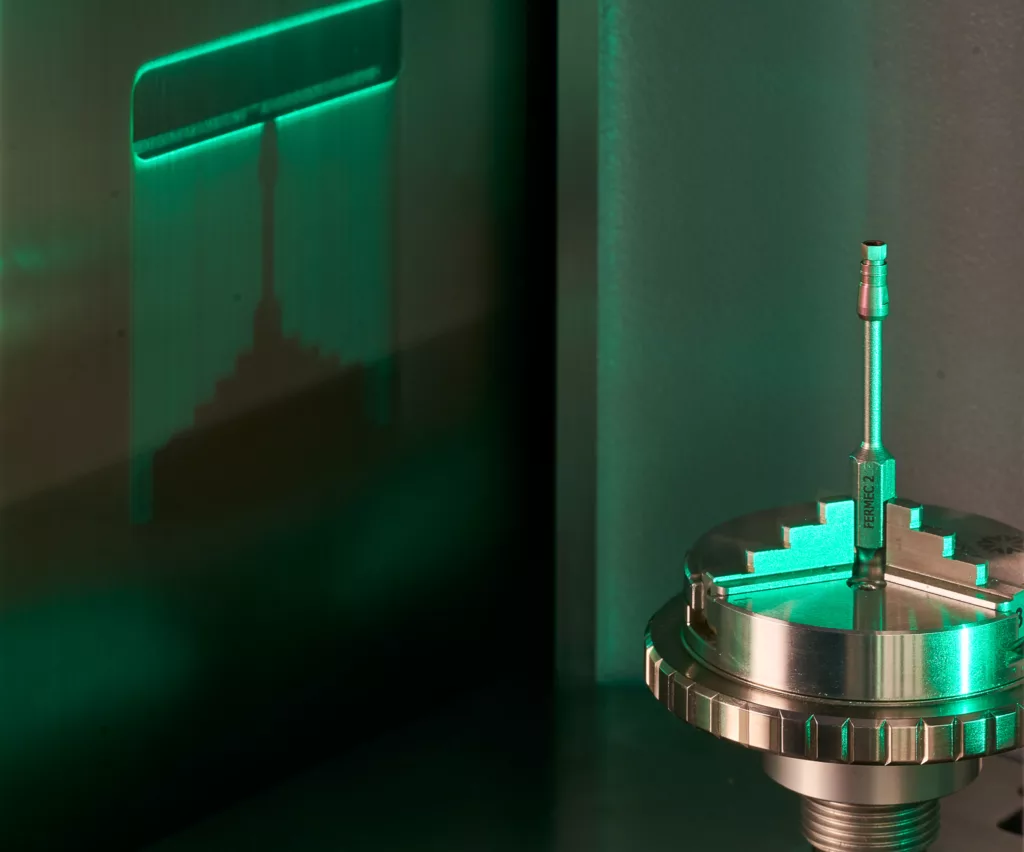

VICIVISION manufactures non-contact optical machines that measure the external profile of turned and ground parts, which ranges from shafts to micro-mechanical parts used in industries such as dental and watchmaking. VICIVISION measuring systems are distributed worldwide and used directly on the shopfloor. Our machines have been designed to operate effortlessly and efficiently ensuring customers reduce waste while optimising their investment.

Expert Knowledge

Whether you are looking to streamline your inspection or improve the quality of parts you are producing, VICIVISION can provide expertise and experience to find the right solution for you. We have unrivalled knowledge in how to maximise the productivity and reliability of your quality control processes, helping you to save the most time and amplify your inspection.

VICIVISION UK is a specialist in providing high performance, non-contact measurement systems for turned parts that can operate directly on the shopfloor next to sliding head machines. By partnering with VICIVISION UK, companies can be confident that they are getting the best possible solutions for inspecting and improving the quality of their turned parts.

VICIVISION offers a range of optical measuring machines, seamlessly catering to a vast spectrum of industries and part sizes, ensuring that every component, from delicate micro-components to large machine parts, is measured with unwavering precision. Whether it’s the demanding precision of the oil and gas sector, the cutting-edge technology of aerospace, the life-critical accuracy of medical devices, or the robust demands of automotive manufacturing.

Regardless of the machine’s size or the component’s dimensions, VICIVISION remains steadfast in its commitment to unwavering precision and at the forefront of inspection innovation. The measurement process remains consistent across the entire range of machines, ensuring that every measurement, from the tiniest micro-component to the largest machine part, is made with the same level of accuracy and exactitude.

VICIVISION UK is a specialist in providing high performance, non-contact measurement systems for turned parts that can operate directly on the shopfloor, measuring cylindrical components such as but not limited to; valves, screws and camshafts to guarantee turned part quality on the shopfloor.

VICIVISION manufactures non-contact optical machines that measure the external profile of turned and ground parts, which ranges from shafts to micro-mechanical parts used in industries such as dental and watchmaking. VICIVISION measuring systems are distributed worldwide and used directly on the shopfloor. Our machines have been designed to operate effortlessly and efficiently ensuring customers reduce waste while optimising their investment.

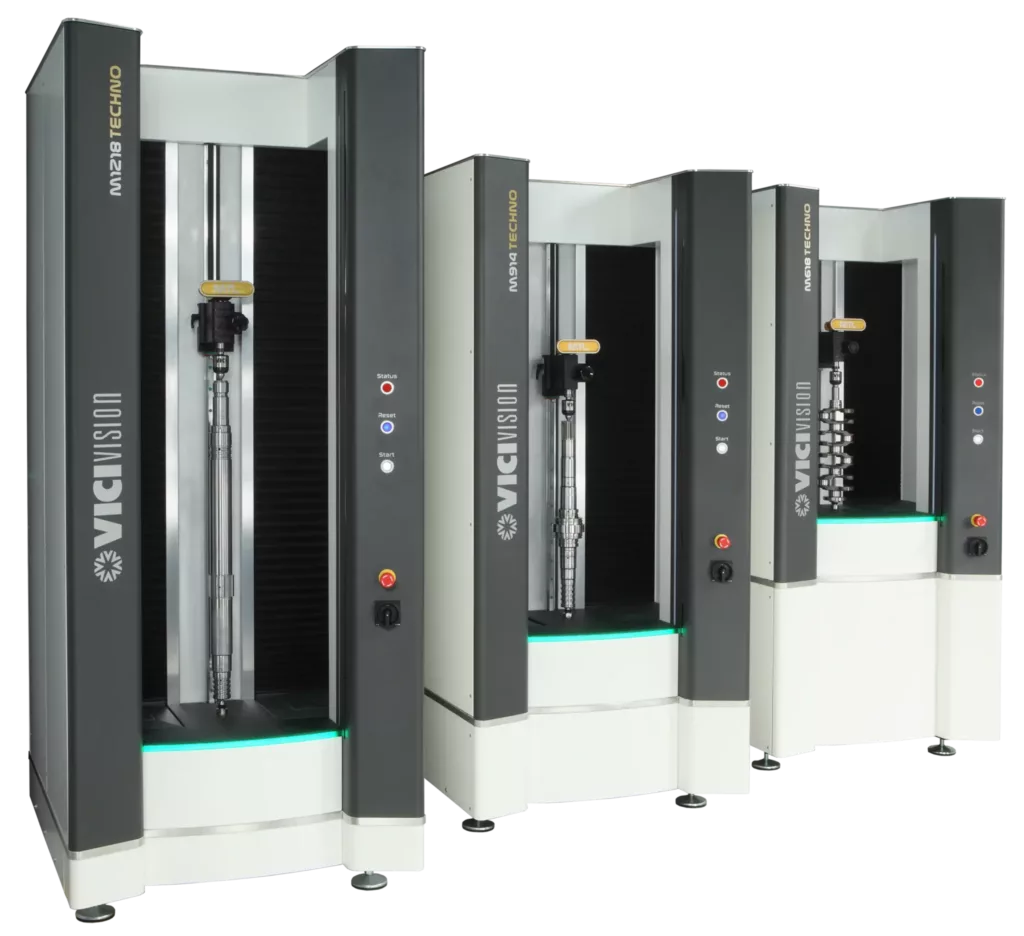

The Techno range from VICIVISION is designed specifically for measuring turned parts, such as those used in the automotive, aerospace, and medical industries. The range includes different models, such as Techno which offer a variety of measurement capabilities and features.

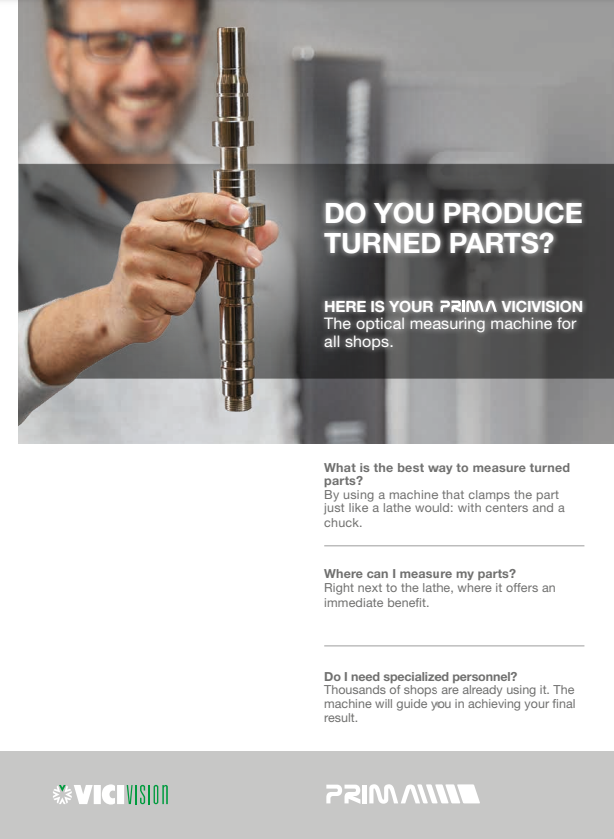

Bring precision to turned part measurement with the PRIMA. Eliminate unnecessary rejects and downtime, speed up processes, simplify tracking, and achieve precise quality control for a fast ROI and maximum throughput.

Place and press makes operation easy. Operators can place a part anywhere in the field of view and draw edges with touch screen motions and multi-gesture technology, allowing the Metrios to take care of the rest with auto-position detection for precise measurement in seconds.

Trust Precision Engineering,

Nottingham, United Kingdom

Learn how Trust Precision Engineering invested in two VICIVISION Techno 304 advanced turned-part measurement machines, supplied by VICIVISION UK, to guarantee accurate, reliable and consistent quality measurement data for their components.

Discover accuracy, precision and industrial quality control with the full range of VICIVISION measurement technologies.

Discover accuracy, precision and industrial quality control with the Metrios range of optical measurement machines.

Brochure

Discover ultra-fast measurements for turned parts with the PRIMA.

Learn more about our optical measurement machines, discuss your applications or request more information by filling out the form to the right. One of our expert engineers will be in touch to discuss everything VICIVISION.

Or call us on 01283 499566

Office Address

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House, Woodyard Lane,

Foston, Derby, DE65 5BU