Accurate and efficient data transfer plays is crucial for modern manufacturers.

Traditional data transfer methods, often reliant on manual data entry, are prone to errors, which can lead to costly consequences such as scrap, rework, spindle collisions, and extended production times.

To address these challenges, manufacturers are increasingly seeking advanced data transfer solutions.

Secure and automated solutions offer significant advantages, including smoother production processes, minimal manual intervention (if any) and enhanced quality control to ensure consistent, reliable information and the use of in-tolerance tooling throughout the manufacturing cycle.

This not only reduces the risk of errors but also increases overall productivity and operational efficiency.

ZOLLER offers a range of comprehensive data transfer solutions specifically designed for the manufacturing industry.

These solutions seamlessly integrate with existing shopfloor processes, ensuring the secure and automated transfer of accurate measurement data. ZOLLER’s data transfer options also track tool wear and discrepancies, ensuring that only functioning and in-tolerance tools are utilised and eliminating the potential for operator error.

By adopting ZOLLER’s secure and proven data transfer solutions, modern manufacturers can gain a significant competitive edge, achieving higher production rates, improved product quality, and reduced operational costs.

ZOLLER’s data transfer solutions offer a range of options to cater to the variety of manufacturing requirements. From user-friendly QR codes designed for straightforward tool identification and data transfer, to RFID chips facilitating rapid and secure communication, ZOLLER can provide a data transfer solution to optimise any production process.

What is the range of data transfer solutions from ZOLLER?

Data Output

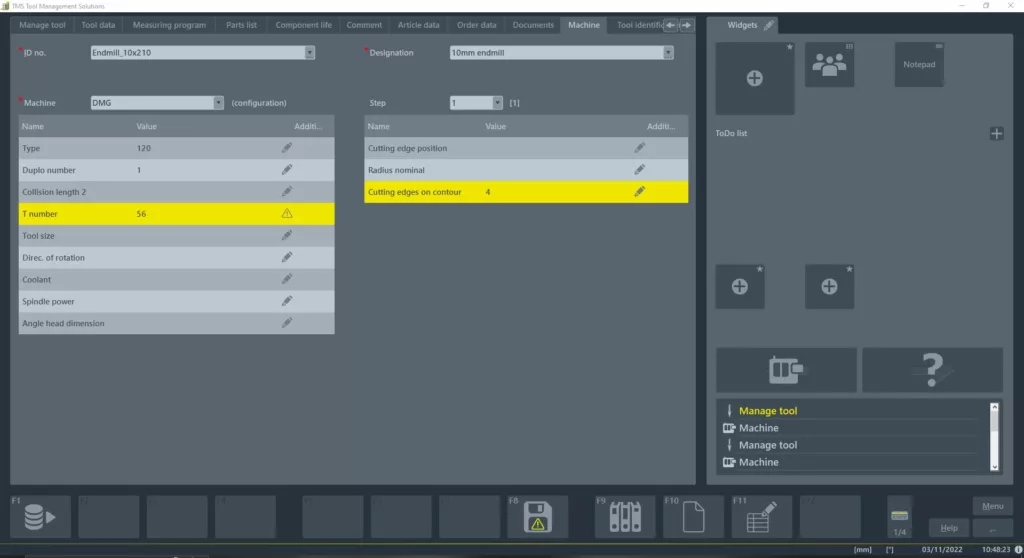

This versatile solution transforms tool measurements from any ZOLLER tool presetter into a format compatible with the specific machine controls. This allows for seamless data integration regardless of the presetter or machine tool model.

zidCode

zidCode utilises QR codes printed on labels which are scanned at the machine tool, automatically inputting the correct tool data from the presetter onto the machine. This eliminates any manual data entry errors, offering a simple and effective data transfer solution.

zidCode 4.0

This innovative solution utilises a network connection to transfer tool measurements directly from the ZOLLER database to the machine tool. This real-time data exchange ensures the machine utilises the most accurate tool information, accessible through a scannable data matrix code.

RFID Chip

RFID chips are a secure data transfer method that embeds an RFID data chip within the tool assembly. The chip stores all of the relevant tool information which is automatically transferred to the machine tool.