Multi-Sensor Measurement Systems

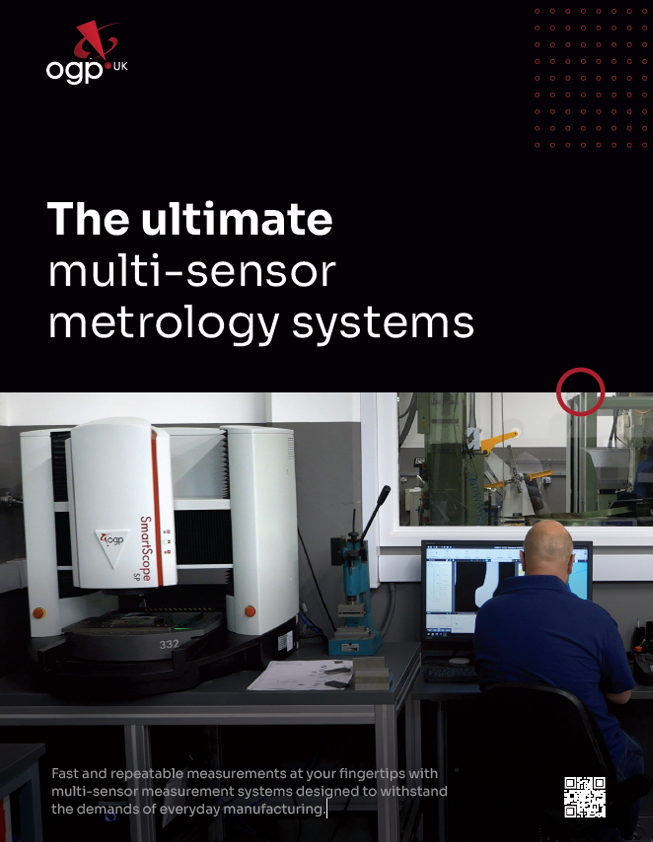

OGP UK provides fast and repeatable measurements at your fingertips with multi-sensor measurement systems designed to withstand the demands of everyday manufacturing. For 100% reliability in inspection, fast measurements of multiple parts in one cycle, and accuracy OGP provides confidence, when results matter.

Unrivalled Expertise

For Measurement

As the UK’s sole partner for OGP products, OGP UK serves the whole of the UK direct from the Advanced Innovation Centre in Derby. We offer a wide range of solutions for all part inspection requirements, as well as service and maintenance, training, installation and subcontract measurement.

Working With

All Industries

OGP UK has a long history of working with a range of companies throughout the UK who trust our knowledge and expertise to help them transform their inspection capabilities. We work with companies from all industries, so whether you are a small independent or a large multi-national, we promise to work with you to help you achieve optimal performance and end-product excellence

Multi-sensor metrology uses multiple sensors to measure different aspects of a workpiece. It is becoming increasingly important in the manufacturing industry because it offers a number of advantages over traditional single-sensor metrology systems; including speed, versatility and accuracy.

Whether you are looking to streamline your inspection or improve the quality of parts you are producing, OGP can provide expertise and experience to find the right solution for you. We have unrivalled knowledge in how to maximise the productivity and reliability of your quality control processes, helping you to save the most time and amplify your inspection.

Coordinate measuring machines (CMMs) have long been the measurement standard technology in the manufacturing industry. However, the development of multi-sensor metrology has introduced a new dimension to component analysis, offering a more versatile and comprehensive approach to measurement and even greater levels of inspection for all industries. Multi-sensor metrology shines in its combination of contact and non-contact sensors, enabling comprehensive and efficient assessment of complex geometries, surface characteristics, and material properties.

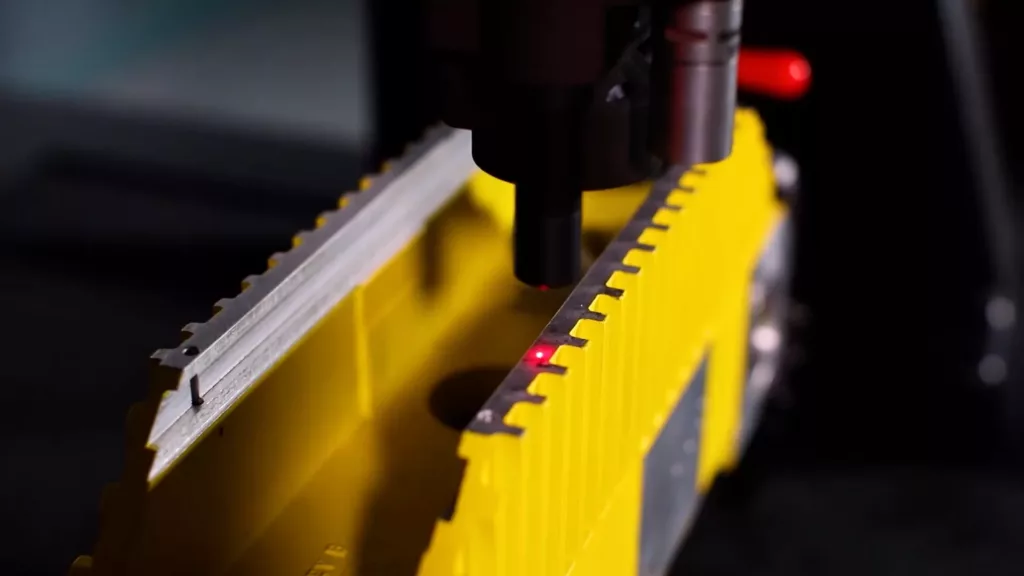

Non-contact measurement sensors are modern metrology technologies that obtain measurement data from a component without physical contact, eliminating the risk of influencing the shape, surface or component itself. The sensors can be used to measure a wide variety of objects with intricate features and complex geometries with superior reliability and repeatability to reach angles and dimensions previously impossible.

OGP UK provides the best-in-class multi-sensor measurement systems, combining contact and non-contact inspection sensors for unrivalled performance in the quality control of manufactured parts and components. Non-contact measurement systems have developed a multitude of sensors to achieve advanced measurement and inspection capabilities, as well as more accurate and repeatable data results.

Multi-sensor measurement provides futureproof capabilities to meet any production requirement. One OGP multi-sensor system can do the work of multiple machines in one measurement programme, delivering improved productivity, more accurate results and in a reduced footprint. The combination of optics, probes, lasers and rotaries provides unrivalled performance for modern manufacturing.

Multi-sensor metrology uses multiple sensors to measure different aspects of a workpiece. It is becoming increasingly important in the manufacturing industry because it offers a number of advantages over traditional single-sensor metrology systems; including speed, versatility and accuracy.

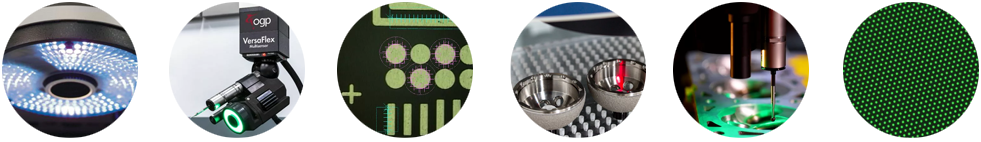

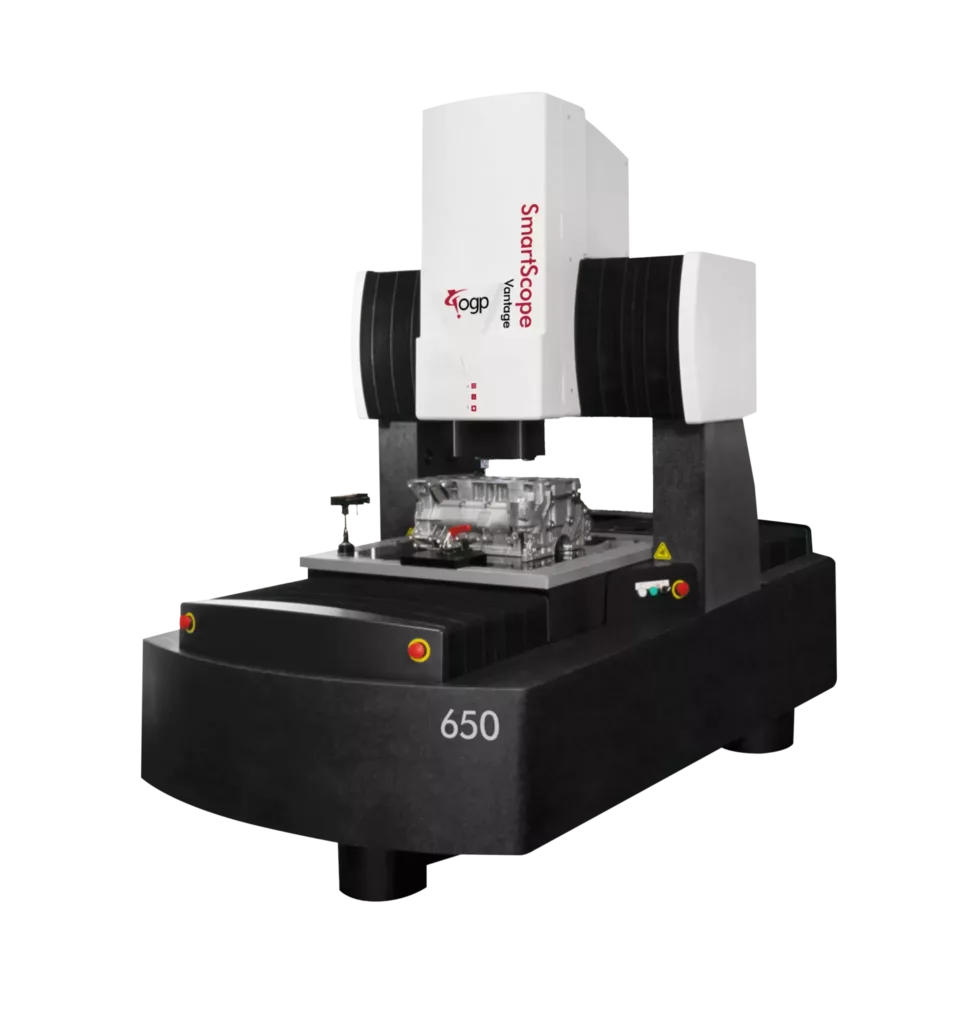

OGP’s flagship SmartScope Vantage is an unrivalled 3D multi-sensor measuring machine designed for supreme three-dimensional measurement accuracy and enhanced throughput. Delivering optimal optical performance, it sets the bar for measurement operations’ accuracy, repeatability, and speed. Configure bespoke measurements for any part, irrespective of complexity, conditions, or challenges.

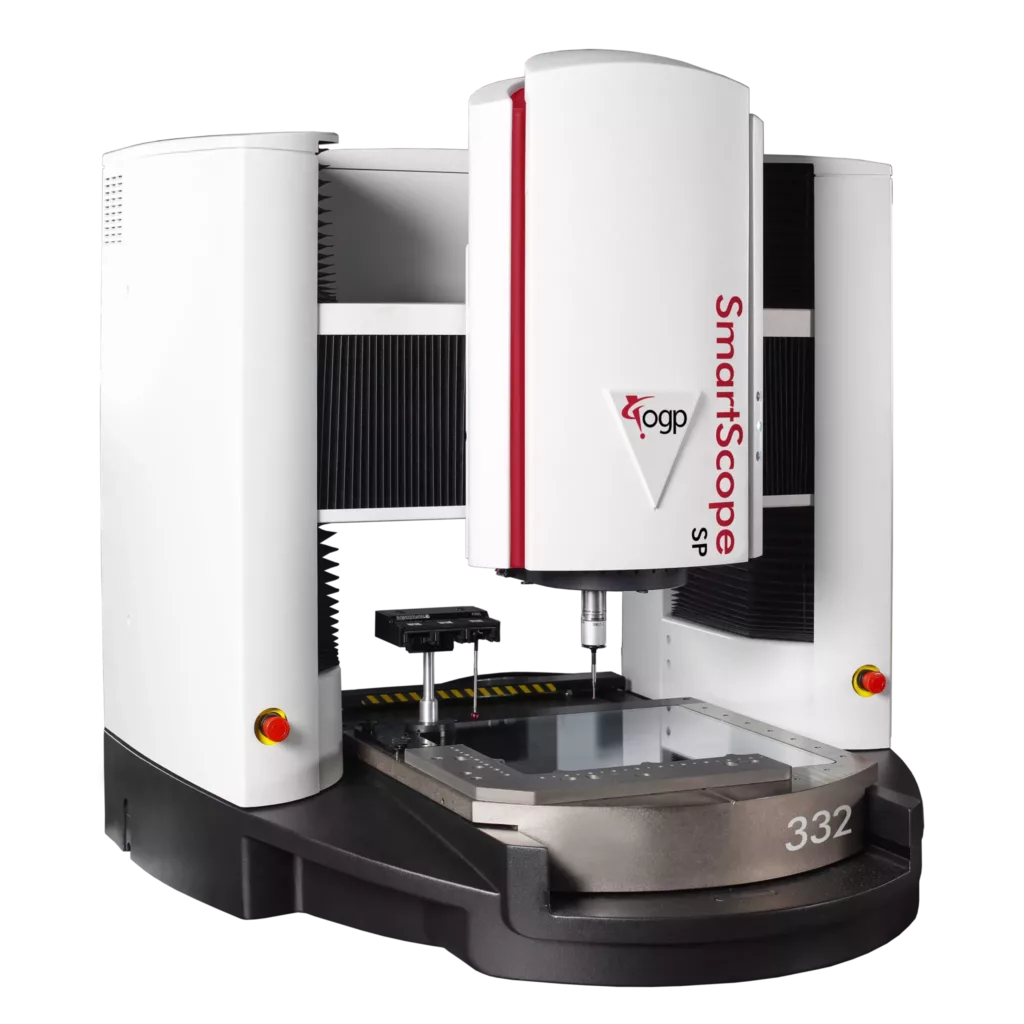

The SmartScope SP’s superior mechanics are meticulously designed for optimised dynamic data acquisition, essential for effective scanning probe performance with complex parts.

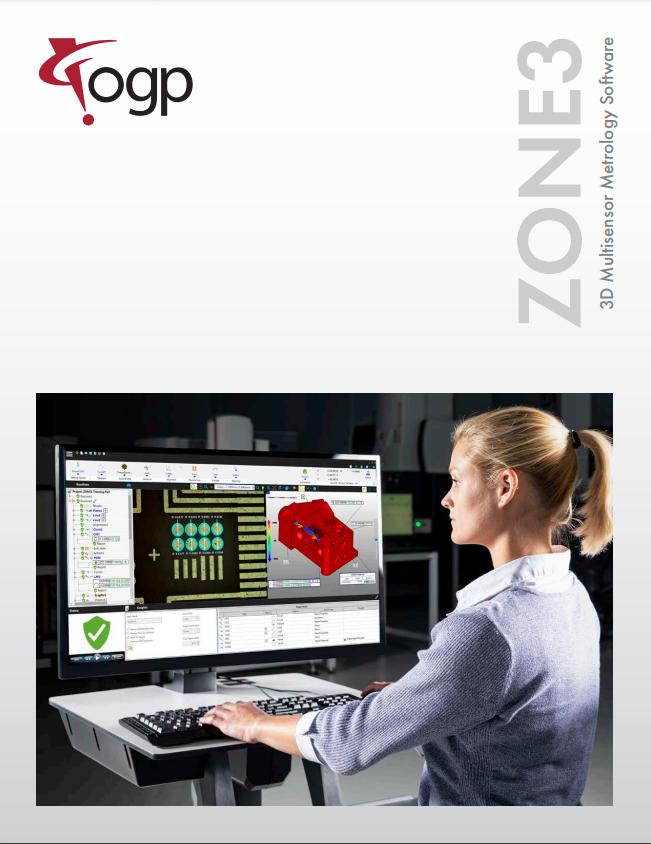

ZONE3 metrology software represents a new way of working with multi-sensor measurement systems. Its built-in 3D animations clearly display relationships between parts, sensors, datum alignments and machine tooling.

Apacor Medical Diagnostics,

Wokingham, United Kingdom

Learn how Apacor invested in a SmartScope CNC 200 multi-sensor metrology machine from OGP UK, allowing them to measure their intricate and complex components faster, more accurately and more consistently.

Discover how multi-sensor metrology solutions can transform your business.

Portfolio

Discover the full range of OGP multi-sensor measurement systems.

Brochure

Discover the world-leading measurement software, ZONE3.

Learn more about OGP’s non-contact measurement machines, discuss your applications or request more information by filling out the form to the right. One of OGP’s expert engineers will be in touch to discuss all things multi-sensor measurement.

Or call on 01283 585933

Office Address

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House, Woodyard Lane,

Foston, Derby, DE65 5BU