Manufacturing data collection and analysis has become invaluable, enabling organisations to analyse all production variables, including machine average speed, changeover time, machine downtimes, product rates, and scrap, to identify and address issues. With so much data now available, data analytics is becoming vital in key industries such as manufacturing, aerospace, and automotive as companies are increasingly beginning to understand the power of data.

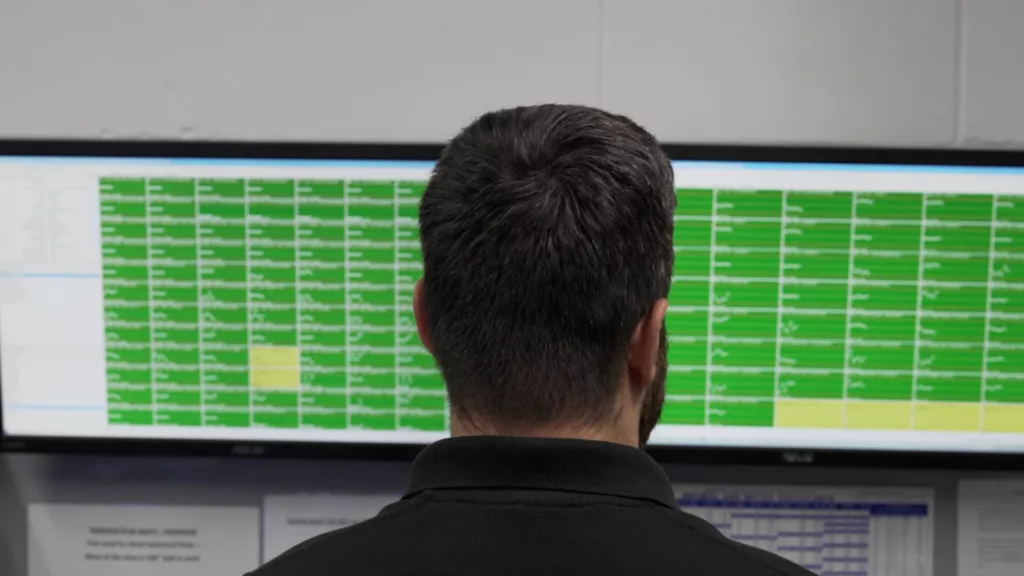

Clear, accurate, and accessible data is essential for continuous shopfloor improvements because without complete visibility and understanding, production productivity can become reduced. Organised and visualised data provides greater understanding of the shopfloor and its processes.

Prolink UK is the world-leader in shopfloor data management software solutions, providing scalable, intuitive and integrated software solutions that empowers manufacturers with real-time data monitoring, automated reporting and unrivalled integration to elevate operational efficiency and product quality. Prolink’s comprehensive suite of statistical process control software solutions offers innumerable benefits to enhance the productivity and quality of the shopfloor.

5 ways Prolink software solutions will revolutionise your shopfloor

1. Gain full control and management of shopfloor data

Prolink collects data from a variety of sources, including coordinate measuring machines (CMMs), electronic gages, and PLCs, and analyses it in real time to identify potential quality problems, trends, and patterns. Prolink software aids decisions about process improvements and generates detailed reports to provide complete visibility and management of quality control processes. Prolink software solutions can be installed across multiple sites, departments and shopfloors to provide consistent reporting and quality management no matter the location.

2. Eliminate human error

Prolink software can be used to track machine downtime, identify bottlenecks, and optimise production schedules. This leads to significant improvements in efficiency and output, as well as reduced costs and human errors. Prolink’s automated data collection software streamlines shopfloor operations by eliminating the risks and inefficiencies of manual data input and collection. It automatically imports data from across the shopfloor and generates reports, eliminating the need for manual data entry. This reduces the risk of errors and empowers businesses to identify and address problems early on, as well as make data-driven decisions that enhance productivity and production processes.

3. Fully adaptable to every shopfloor

Unlike other software solutions, Prolink can seamlessly integrate with any shopfloor, collecting data from a variety of machines, devices and systems, including CMMs, electronic gages, PLCs, MES systems, ballooning and database providers, and Pilot software. With a variety of customisable reporting and dashboard capabilities, Prolink software provides an all in one solution and can be scaled to meet the needs of any manufacturing environment, from small manufacturers to larger organisations with multiple shopfloors, across multiple sites.

4. Management at every level

Prolink offers a range of licenses that provide real-time visibility into shopfloor data, allowing users of all levels to see how their processes are performing immediately. Organisations can customise data access and reports to their specific sector, giving management greater visibility across the shopfloor and providing engineers with the data they need to do their jobs effectively. Its customisable reporting and dashboard capabilities allow users to create reports and dashboards that meet their specific needs, drilling down into shopfloor data to identify the root cause of any problems. This enables managers to take corrective action quickly and effectively.

5. Access data anywhere, anytime and on any device

Prolink’s cloud-based software solutions are compatible with all desktops, mobile devices and tablets with an internet connection, providing immediate access to shopfloor data anywhere, anytime, and on any device. Multiple users can access the same data simultaneously, making it easier than ever to access and share data with team members to collaborate.