3D printing has profoundly impacted various industries and aspects of modern life, from healthcare and manufacturing to customisation and sustainability. The adoption of 3D printing across the world is on the rise, and the growth forecast for the 3D printing market is expected to reach around GBP 40 million by 2028.

SYS Systems is the platinum partner of Stratasys in the UK, supplying and supporting the full range of world-renowned 3D printing technologies from prototyping through to production.

As 3D printing technologies continue to advance, more and more industries are turning to 3D printing, to transform their manufacturing processes, introduce new techniques, speed up product development, drive innovation, creativity, and business growth.

10 ways 3D printing is revolutionising the world we live in

1. Customisation and personalisation:

3D printing technologies allow for the creation of highly customised and personalised products to meet specific preferences and requirements, from custom usb holders to customised jigs and fixtures for industrial production.

2. Art and design freedom:

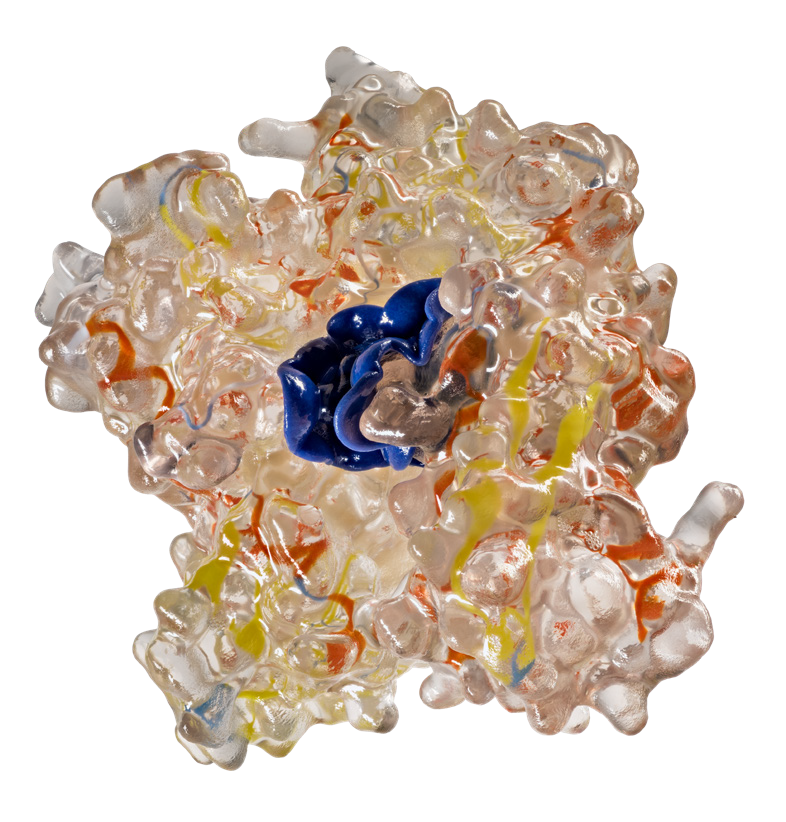

Artists and designers have embraced 3D printing as a medium for creating intricate and unique pieces of art and design. It provides a new level of creative freedom, allowing artists to experiment with materials, textures, and structures beyond the capabilities of traditional sculpting or crafting methods. Nick Ervnick applies tools and techniques from 3D printing in order to explore the aesthetic potential of sculpture.

3. Prototyping and rapid product development:

3D printing has significantly accelerated both prototyping and product development processes. This speed in product development has reduced time-to-market for many global products and industries, including SYS customers Speedo and Revo Developments who invested in the Polyjet Connex and Stratasys F370 FDM machines.

4. Supply chain resilience and localised manufacturing:

3D printing has the potential to decentralise manufacturing and enhance supply chain resilience. By enabling localised production, it reduces the need for centralised factories and extensive transportation of goods, allowing for on-demand production of critical components locally.

5. Medical advancements and healthcare solutions:

3D printing has made significant contributions to the medical field, allowing for the production of complex and intricate structures vital for modern medicine including building prosthetics and modelling internal organs to develop life-saving treatments. Many surgeons are practicing pre-ops using 3D printed parts.

6. Educational and research advancements:

3D printing has become a valuable tool in education and research, with many educational facilities investing in 3D printing, allowing students, educators, and researchers to bring their concepts and ideas to reality. SYS customer and leading educational facility, the University of Derby invested in PolyJet500 Connex3 and now use the machine to create models for experiments, medical research, and scientific studies.

7. Aerospace and automotive industry innovation:

Aerospace and automotive industries have been revolutionised by 3D printing, producing customised, innovative, and complex lightweight components to reduce fuel consumption and enhance overall efficiency. Did you know? More than 1000 flight parts were 3D printed on Stratasys FDM production systems for the Airbus A350.

8. Food and culinary innovations:

Chefs and culinary innovators are becoming more creative whilst also helping to reduce waste and improve food sustainability by developing alternative ingredients and combinations using 3D printers. Celebrity chef Marco Pierre White launched his 3D-printed vegan “steaks” across the UK as apart of his Redefine Meat company.

9. Construction:

3D printing is being used to create construction components that are building homes and larger structures to provide vital and sustainable housing in a time and cost efficient way. In November 2014, Skanska and Loughborough University signed a deal to develop what they describe as the world’s first commercial concrete 3D printer.

10. Disaster relief and humanitarian aid:

3D printing has played a vital role in disaster relief and humanitarian aid efforts. 3D printers can quickly produce essential items like shelters, water filtration systems, medical supplies, and tools, helping communities in need and providing critical support in emergency situations, including Field Ready, a humanitarian aid and development organisation, use 3D printing technology to produce medical instruments.